If you own or regularly haul a trailer, you already know that the wiring and electrical system is its lifeline. Without properly working lights, turn signals, and brakes, your trailer isn’t just unsafe, it’s illegal to operate on the road. Yet, trailer wiring problems are among the most common trailer issues owners face. They can creep up suddenly, often at the most inconvenient times: right before a long trip, while hauling at night, or even when you’re hooked up at a busy job site.

In this guide, we’ll take a deep dive into the electrical system of trailers, the most common problems with trailer wiring, how to troubleshoot them, and tips on how to fix trailer wiring so your rig runs reliably.

Why Trailer Electrical Systems Are So Vulnerable

Unlike the protected wiring in a vehicle’s body, trailers are exposed to harsh conditions. Think of everything your trailer faces: road salt in winter, water splashes on rainy days, heat in summer, dust on gravel roads, constant vibrations from towing, and even accidental damage during loading or unloading. Over time, these factors wear down insulation, corrode connectors, and cause wires to loosen or break, all of which lead to trailer electrical system problems.

Adding to the challenge, trailers often use a flat 4-pin or 7-pin connector system. While these are standardized, they rely on solid electrical continuity between truck and trailer. Even a tiny amount of rust, a bent prong, or a weak ground wire can cause problems with trailer electrical systems, such as flickering or failing lights.

The Basics of a Trailer’s Electrical System

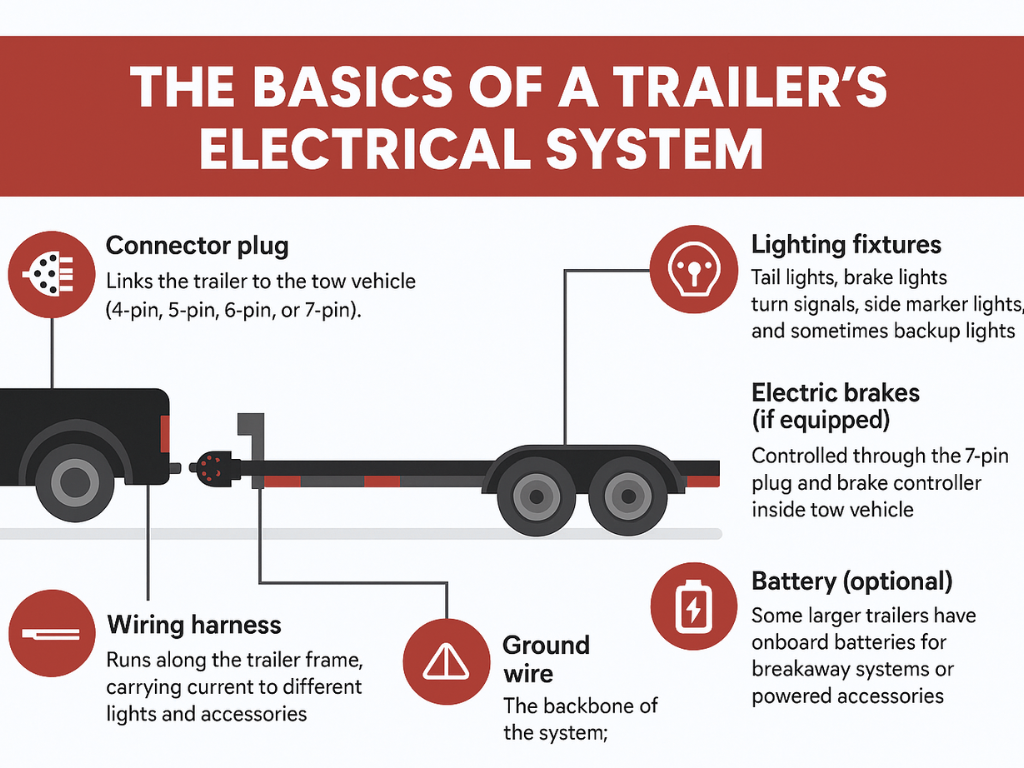

Before jumping into trailer electrical system problems, it helps to know the basics of how a trailer’s wiring works:

- Connector plug: Links the trailer to the tow vehicle (4-pin, 5-pin, 6-pin, or 7-pin).

- Wiring harness: Runs along the trailer frame, carrying current to different lights and accessories.

- Ground wire: The backbone of the system; without a solid ground, nothing works consistently.

- Lighting fixtures: Tail lights, brake lights, turn signals, side marker lights, and sometimes backup lights.

- Electric brakes (if equipped): Controlled through the 7-pin plug and brake controller inside the tow vehicle.

- Battery (optional): Some larger trailers have onboard batteries for breakaway systems or powered accessories.

When one of these components fails, it often leads to problems with trailer electrical systems that require immediate attention.

Common Trailer Wiring and Electrical Problems

1. Lights Not Working at All

If every light is out, the issue usually lies at the connector. A loose plug, corroded pins, or blown fuse in the tow vehicle are likely culprits. In some cases, the ground wire may be disconnected or rusted away, a classic example of problems with trailer wiring.

2. One Function Not Working

If brake lights work but turn signals don’t, the issue is usually isolated to a specific circuit. A broken wire, bad bulb, or corroded socket may be to blame.

3. Dim or Flickering Lights

This often indicates a poor ground connection. Since trailers rely on a single ground wire, any rust or looseness where it attaches to the frame can cause weak current flow and recurring trailer wiring problems.

4. Brakes Not Engaging

For trailers with electric brakes, wiring issues are common. A faulty brake controller, broken blue wire (which carries brake signal), or corroded connection can prevent the brakes from activating, creating serious trailer electrical system problems.

5. Short Circuits & Blown Fuses

Frayed wires rubbing against the trailer’s metal frame often lead to short circuits. This not only blows fuses but can also melt wires or cause sparks, a dangerous problem with trailer electrical systems if left unaddressed.

6. Corrosion in Connectors

Moisture, road salt, and general exposure corrode the metal contacts inside the plug. Even a light greenish buildup can block electrical current, leading to intermittent operation and frustrating problems with trailer wiring.

Troubleshooting Trailer Electrical Problems

Diagnosing trailer wiring problems doesn’t have to be intimidating. Here’s a step-by-step process you can follow with just a multimeter and some patience:

- Start at the connector. Check that it’s fully seated, free of rust, and that all pins are straight.

- Test the tow vehicle. Plug in a tester or use a multimeter to confirm the truck is sending the correct signals.

- Check the ground. Look for a clean, tight ground connection between the trailer frame and wiring.

- Work down the harness. Follow the wires along the frame, looking for cuts, burns, or pinches.

- Inspect bulbs and sockets. Remove the lens covers and ensure the bulbs are intact and seated correctly.

- Test continuity. With a multimeter, check for current flow across wires suspected of being faulty.

By following these steps, you’ll quickly learn how to fix trailer wiring and address many common problems with trailer electrical systems before they worsen.

Preventative Maintenance for Trailer Wiring

Like any system, prevention saves more headaches than repairs. A few small habits can dramatically reduce trailer wiring problems:

- Use dielectric grease on connectors to block moisture and corrosion.

- Secure wires tightly along the frame with clips or loom to prevent rubbing and chafing.

- Clean plugs regularly, especially after winter driving.

- Check grounds often, ensuring bare metal-to-metal contact.

- Cover connectors with a weatherproof cap when not in use.

- Replace damaged wiring instead of patching with tape, heat shrink tubing, or weatherproof connectors are better.

Consistent care is the most reliable method of knowing how to fix trailer electrical systems before issues lead to costly breakdowns.

When to Call a Professional

Some issues are simple to repair, but others, especially involving brakes or breakaway systems, may require a professional. If you’ve tried troubleshooting and the issue persists, or if you’re noticing frequent fuse blowouts, it’s best to have an expert perform a full inspection. Certain problems with trailer wiring or problems with trailer electrical systems require advanced testing equipment and experience to resolve correctly.

Other Trailer Problems

Take a look at the table below for helpful guidance and troubleshooting advice on additional trailer concerns. We’ve assembled details on common mechanical, safety, and maintenance issues to help you find solutions quickly and keep your trailer operating safely.

Keep Your Trailer Safe with Our Service & Repair

Trailer wiring problems and trailer electrical system problems are more than minor inconveniences, they can quickly turn into roadside breakdowns, costly tickets, or even dangerous accidents. At Four Winds Trailers, we know how important it is to keep your trailer in top condition. That’s why our expert team offers complete inspection, diagnostics, and repair services to catch issues before they become major headaches.

From faulty connectors and corroded plugs to full wiring replacements, we have the experience and parts on hand to handle it all. Our shop stocks high-quality wiring kits, durable connectors, and lighting systems designed to keep your trailer road-legal and dependable.

Don’t let problems with trailer wiring or a failing electrical system keep you off the road. Trust Four Winds Trailers for reliable service, fast repairs, and the parts you need to haul with confidence.